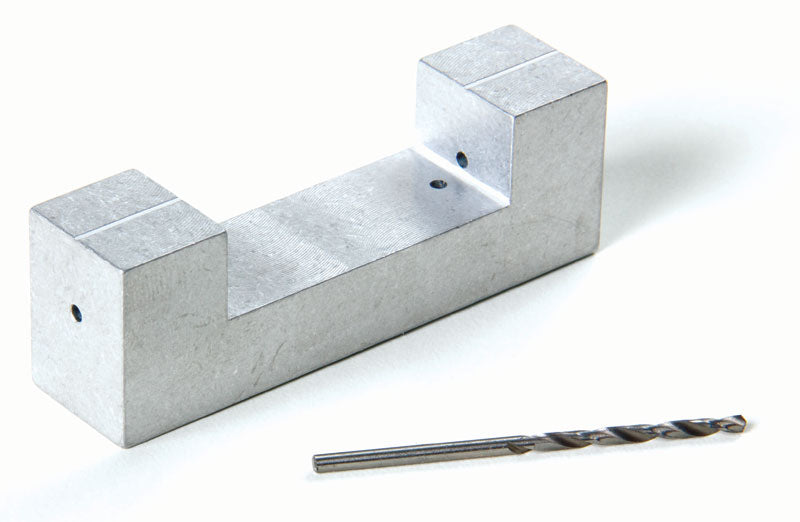

Build – Axel Slot Jig AArmstrong Hobby

$ 9,95 $ 5,97

The Axel Slot Jig tool will improve the speed of your pinewood derby car by:

- Axle Slot Preparation – For kits with axle slots, the Pro-Body Tool ensures accurate axle positioning by allowing you to drill accurate axle pilot holes into the existing axle slots with a hand drill!. The pilot holes ensure that the axles are mounted square and true on the car. Improved axle mounting accuracy equals greater speed!

- Axle Hole Drilling – For races which allow axle holes, the Pro-Body tool serves as a guide for drilling accurate axle holes with a hand drill. Again, improved axle mounting accuracy equals greater speed!

- Axle Hole Re-drilling – For kits with the screw and 3/8″ dowel rod axle system, the Pro-Body Tool (Model 5148) allows you to accurately re-drill the axle pilot holes.

When using nail-type axles, the Pro-Axle Press and Pro-Body tool work together to make a well-aligned and smooth rolling car.

The Pro-Body Tool is designed to accurately straighten existing axle slots or create new axle holes Using a hand drill on BSA and PineCar kits. The required #44 drill bit is included.

Instructions:

Test fit the Pro-Body tool on the bottom of the block with the two “ears” positioned on the sides of the block. If the tool will not fit onto the block, use coarse grit sandpaper to reduce the width of the block until the tool fits snuggly. If the tool is loose,tighten the fit by placing a piece of paper-folded as needed between one ear of tool and the block.

To create Pilot Holes in Axle Slots

- Use a square to draw a straight line on one side of the car starting at the middle of the Axle slot, and extending to the top of the car. (Or measure the distance from one end of the block to the middle of an axle slot and transfer that measurement to the top-side of the block. Then use a ruler to draw a line from that measurement to the center of the axle slot).

Repeat step 1 for the other slot.

To Create New Axle Holes

- Measure and mark the desired position of the new axle holes on one side of the block. Extend the mark from the bottom of the block to the top of the block using a square (0r measure and mark near the bottom of the block and near the top of the block, and then jointhe line with a pencil and ruler). Holes for extended wheelbase are typically positioned 5/8” from the end of the block.

Repeat step 1 for the other end of the block.

Position the Tool

- Position the tool on the bottom of the car with two “ears” on the sides of the block. Align the index mark with the line on the block. Clampthe tool in place.

- Hold the block firmly,position the drill bit in the hole,and slowly drill ¾” into the block.

- Without releasing the clamp,turn the tool and block over,and drill the second hole.

Repeat steps 4 to 5 for the other 2 holes.

Prompt Shipping and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other international carriers gives us the ability to provide an array of shipping services. Our warehouse personnel are extremely skilled and will package your goods in accordance to our exact and precise specifications. Your products will go through an extensive inspection and will be securely secured prior to being shipped. Every day, we send thousands of packages to customers from all over the world. This is an indication of our determination to become the biggest online retailer in the world. Warehouses and distribution centers can be found in Europe and the USA.

Note: Orders that contain more than one item are assigned a processing time in accordance with the item.

Prior to shipment the items, our staff will carry out an extensive inspection of the items you purchased. Today, most orders will be shipped within 48 hours. The estimated delivery time is between 3 and 7 days.

Returns

Due to multiple parties such as the factory and the warehouse, we are unable to effectively manage inventory. The actual stock can be changed at any time. Be aware that it is possible for your order to be out of stock after you have made the order.

The policy is 30 days. We cannot exchange or refund your order after 30 days from the date of purchase.

Your item should be in its original packaging and in good condition. It must also not be used. You must have the item in the original packaging.

Related products

CR-Wood Car Racing

Decals – Pinecar Wheel Flare Rub-on Decals-Juiced AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

Car – Pinecar Muscle Car Full Body Pre-Cut Design AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

Decals – Pinecar Wheel Flare Rub-on Decals-Cyclone AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

Decals – Pinecar Wheel Flare Rub-on Decals-Green Snake AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

Decals – Pinecar Wheel Flare Rub-on Decals-Fire Ball AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

Decals – Pinecar Wheel Flare Rub-on Decals-Pride AArmstrong Hobby

CR-Wood Car Racing

CR-Wood Car Racing

CR-Wood Car Racing

Car – Pinecar Stock Car Full Body Pre-Cut Design AArmstrong Hobby

CR-Wood Car Racing

Car – Pinecar 4X4 Truck Full Body Pre-Cut Design AArmstrong Hobby

CR-Wood Car Racing